Product Details:

Payment & Shipping Terms:

|

| Cutting Materials: | Can Cut All Kinds Of Materials | Max. Cutting Thickness: | Less Than 100mm ( Depend On The Actual Materials) |

|---|---|---|---|

| X-axis: | 1500mm | Y-axis: | 3000mm |

| Z-axis: | 200mm | Repeatability: | 0.02mm |

| X.Y Speed: | 0-15meter/min | Control Accuracy: | ±0.01mm |

| Cutting Accuracy: | ±0.1mm | Power: | 37KW |

| Max Flow Rate: | 3.7L/min | HP Generator: | USA (Accusteam/Hypertherm) |

| Sand Hopper: | Side-handing Sand Hopper | CNC Controller: | MITSUBISHI AC Servo Driver And Motor |

| Main Motors: | SIEMENS | Ball Screw: | HIWIN |

| Shift Valve: | Bosch | Electric Appliance: | Schneider |

| PLC: | Siemens | ||

| High Light: | cnc cutter machine,5 axis water jet cutting machines |

||

4 axis 37KW Steel Water Jet cutting machine with cutting size 1500*3000mm,Gantry type

Besides the 3 basic axis, there are other 2 axis, one of them is for rotation, another is angle axis witch is manual without participating in the linkage, so we just call it 4 axis water jet cutting machine.

The tilt angle of 4 axis machine is much smaller than 5 axis machine, the angle is 5 degrees. but it is enough to solve the problem of the cutting slope of water jet. during the cutting process, it can do angle compensation to confirm the incision Completely vertical. The cutting accuracy is 0.1mm,can totally meet the requirements of a variety cutting. This equipment has achieved good results in a number of cutting areas, mainly in significant decline of the processing costs and greatly improve of the processing efficiency.

Typical applications:

It has a more gratifying effect in marble mosaic processing. When the cutting head keep 5 degrees, the section will be different. when we combine the two cutting blocks,there is no gap on the upper surface, and a little big gap exists on the lower surface. So there is no need to manually secondary polishing, reducing processing costs, improve effectiveness. the more important is to improve the quality of mosaic, so this 4 axis machine makes it much easier to achieve complex mosaic production. It also has a remarkable effect in cutting glass straight holes application. For example,when we cut straight holes on glass, we can keep the same speed to achieve the desired effect.

1, Cutting table

1.1. Structure feature

--Casting beam and Y-axis base frame make it have excellent precision and stability.

--Machine table body and water tank which are sub aspect structure, less the pressure of sands and machined parts to moving parts.

--X-axis and Y-axis transmit to rolling nut ball screw mandrel.

1.2. Control system

We adopt the famous NAIKY controlling system and MITSUBISHI AC servo digit driving system and AC servo motors.

1.3. Machine chief technical parameter

Structure: Bridge

Size( X and Y): 3100*1600mm

X-axis: 3000mm

Y-axis: 1500mm

Z-axis: 200mm

Repeatability: 0.02mm

X.Y speed: 0-15meter/min

Control accuracy: ±0.01mm

Cutting accuracy: ±0.1mm

Power: 380VAC, 50HZ, 3 phase 4 wires system.

1.4. Transmission system

We adopt the HIWIN (Taiwan) lead rail and gear rack to ensure accuracy durable and quality.

1.4.1. Prevention system

--over travel auto spacing function and soft spacing function;

--Unique prevention design: new mazy protection and Z-axis totally enclosed professional design prevent sand and water-from eroding the guide screw and lead rail.

1.4.2. Lubrication system

We adopt the auto mass lubrication system to make oil reach every oil site on time and also make table steadier and easier.

1.5. Abrasive cutting system

1.5.1. The cutting efficiency of this machine integrative abrasive cutting head is one of the highest machines in the world.

--it has rectification function and lessens the time of assembling

--changing the wearing parts is very simple

1.5.2. The machine’s HP water switch

--air valve can open and closed the HP water instantaneously.

--with the help of CNC we can control HP water automatically.

--blockage pressure can be adjustable arbitrarily to realize the operation under the low pressure circumstances.

1.5.3. Sand feeding system

Dynamic sand feeding

Manual makes up the sand for the feeder (assisted with sand meter, auto feeder can realize automatically feeding)

1.5.4. DCAS-B sand valve

--Dynamic sand feeding

--Dynamic type comes over traditional type.

--Manual type makes the operation easier.

--With the help of CNC we can control abrasive automatically.

1.5.5. Sand hopper

--Side-handing sand hopper

--There is a window on the side face, it can remind workers when to feed sand

--It can provide the sand consumption every time after it’s filled up

2. HP system

2.1.1. HP generator

--The configurations single pole two-way plunger type intensifier

--The intensifier assembly is imported from the USA (Accusteam/Hypertherm)

--USA pipeline

--Single-row type water filtering system

--Manual pressure regulation function

--Extra pressure auto stop and protection

--Three-ply safeguards

2.1.2. Chief technical parameter

--Max flow rate: 3.7L/min

--Power: 37KW

--Power supply: 380VAC, 50HZ, 4 phases.

3. CNC controller

3.1.1. CNC configuration

--17” LCD liquid crystal display

--DNC on-line working function

--Functions of returning arbitrary point, bending and circular arc working auto deceleration.

--Functions of cutting figure imitation display.

--80GB memory hard disk

--MITSUBISHI AC servo driver and motor.

--1GB memory card

--Multilingual functions (Chinese, English etc…)

--Drive-by-wire and hand-hold controller (according to requests)

3.1.2. Software

NAIKY PCIMC-6A special software is special for this cutting machine.

The functions of PCIMC-6A are as follows:

--Change DXF document which is educed from AUTOCAD into numerical control process.

--Serial communications between PC and CNC.

--Open database can shore parameters, just click the material, parameter will be loaded automatically.

--Calculate length of line and time automatically

--Cutting track auto imitation function

--The functions of lessening speed on the corner remanding material bridging and lancing.

4. Auto abrasive feeding system

--It provides the functions of shorting and sanding sands for the machine, also improves the automation and lessens intensity of labor.

--Capacity: 170L

--High accuracy can remain workers when to feed sands.

5. Auto water cooling system

--Guarantee that hydraulic system can be used circularly.

--Save water

6. Machine parts details

| No. | Name | Model | Specifications | Quantity |

|

1-3 |

CNC water jet cutting machine |

High pressure system: WJ-3742 |

Max. pressure: 420MPA |

1 |

| Cutting table: WJ-L3015 | Cutting size: 3000*1500mm | |||

| CNC control system | Based on Window with NC studio | |||

| 4 | Abrasive feeding system | WJ-A | 170L | 1 |

| 5 | Water cooling system | WJ-B | 1 | |

| 6 | Main motors | // | SIEMENS | |

| 7 | Spare parts | List 1 & list 2 | Free with the machine | free |

| List 1- Special tools | ||

| Item | Main Descriptions | Quantity |

| 1 | 60K intensifier Tool kit ( For H-P Seal) | 1 |

| 2 | Wrench Girth ( For H-P Cylinder) | 1 |

| 3 | Wrench, Spanner ( For end Cap) | 1 |

| 4 | Wrench, Spanner ( For HIGH PRESSURE SWITCH) | 1 |

| 5 | Spanner ( For water filter) | 1 |

| 6 | Blue Lubricant | 1 |

| List 2- spare parts free with the machine | ||

| No. | Name | Quantity(set/pcs) |

| 1 | Ruby | 4 |

| 2 | Nozzle | 1 |

| 3 | HP water switch kit | 1 |

| 4 | HP seal | 1 |

| 5 | LP seal | 1 |

| 6 | LP check valve repair kit | 1 |

| 7 | Filter element ( 5 micron) | 1 |

| 8 | Filter element( 1 micron) | 1 |

| 9 | Filter element(0.5 micron) | 1 |

| 10 | O ring and assembled ferrule | 1 |

| 11 | Accumulator seal | 1 |

| 12 | Accumulator valve pad | 1 |

| 13 | Connecter of pipe | 2 |

| 14 | Shield cap | 2 |

| 15 | Air valve repair kit | 1 |

Machine Chief parts brand and manufacturer comments:

This Machine cutting speed data for reference (the exact cutting speed data depend on the actual real materials)

Conditions:0.25mm ruby,0.8mm nozzle

| Material type | Thickness(mm) | Cutting speed(420MPA model)mm/min |

| Marble | 20 | 480 |

| 30 | 360 | |

| Granite | 20 | 384 |

| 30 | 240 | |

| Brick | 10 | 960 |

| 28 | 360 | |

| Glass | 8 | 1800 |

| 10 | 960 | |

| 18 | 600 | |

| Doubling glass | 21 | 720 |

|

Sponge

|

20 | 8400 |

| 50 | 3600 | |

| 80 | 2400 | |

|

Carpet

|

3-4 | 3600 |

|

Stainless steel sheet

|

1 | 1440 |

| 3 | 720 | |

| 6 | 360 | |

| 10 | 240 | |

| 16 | 120 | |

| 20 | 102 | |

| 30 | 48 | |

| 55 | 12 | |

| 65 | 6 | |

| Steel Sheet | 3 | 1440 |

| 5 | 1020 | |

|

Aluminum Alloy sheet and magnesium alloy sheet |

10 | 480 |

| 20 | 180 | |

| 30 | 120 | |

| 70 | 48 | |

| 80 | 20 | |

| 100 | 15 |

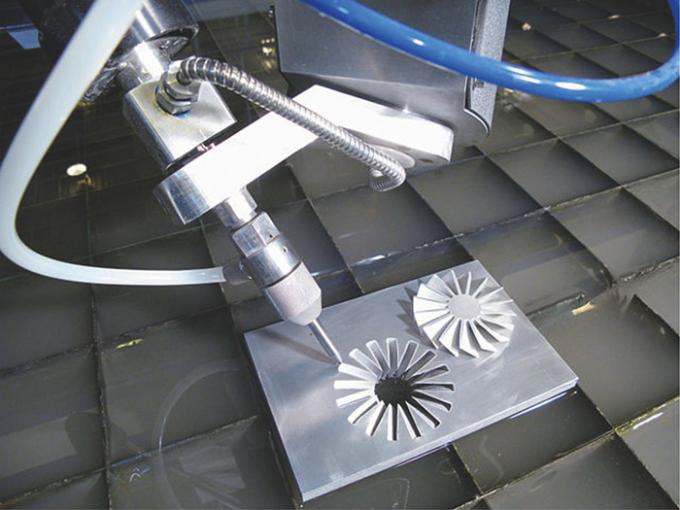

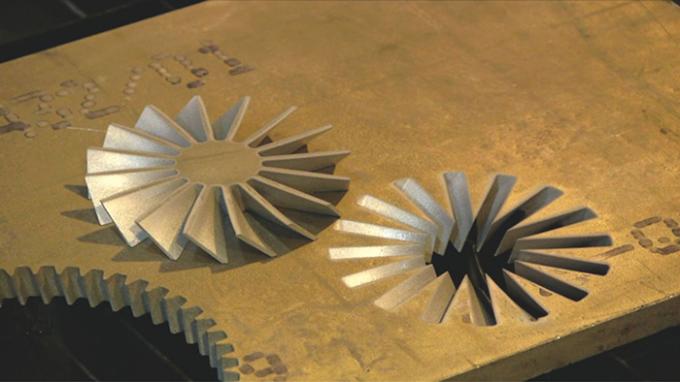

The water jet cutting photos for reference

We can customized different kinds of water jet cutting machines depend on customers actual requirements, welcome to contact us for more informations.